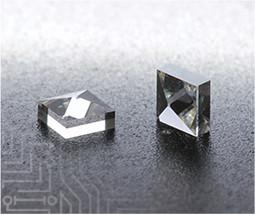

A diamond by far surpasses its main competitors: silicon (Si), silicon-carbide (SiC) and gallium-nitride (GaN) in thermal conductivity. Thermal conductivity of diamond plates is ranging from 1000 to 2000 W/mK, however, due to unique technology our single-crystal subs have shown better results averaging approx. 2100 W/mK.

NDT diamond is able to fully remove the heat or to change temperature of high-power sources in order to prevent overheating, damage and destruction of the working module. Diamond heat sink substrates allow to increase capacity of the operating modules and their life time in extreme conditions. It is very important for semiconductor industry, in wich currently it is not possible to develop UHP and fast processors and it stays only a dream of a technologist at this stage and time.